Mactec was founded in 2004 to fill the void for small footprint, quick turnover unit dose packaging machinery. Our machines are operator-friendly and better suit the ever-changing needs of the pharmaceutical, nutraceutical, and many other industries. Whether you know the exact specifications for your product, or you’re looking for expert guidance on the design, Mactec will partner with you to build a custom solution using one of our versatile lines of packaging machines. Our team of engineers and technicians are prepared to design and build exactly what you need to serve your clients and improve the efficiency of your unit dose production.

Versatile, creative and customized unit dose packaging machines tailored to your companies specifications to meet production needs across a wide array of industries.

Our custom packaging machines range from table-top size to full scale blister packaging, pouch packaging, and monoblock filling systems to give you the finished product result you’re looking for. From blisters, sachets, pouch packets, gummies, tubes and cups, unit dose packaging looks different for every industry.

Find the custom, flexible solution you need to bring your product to market.

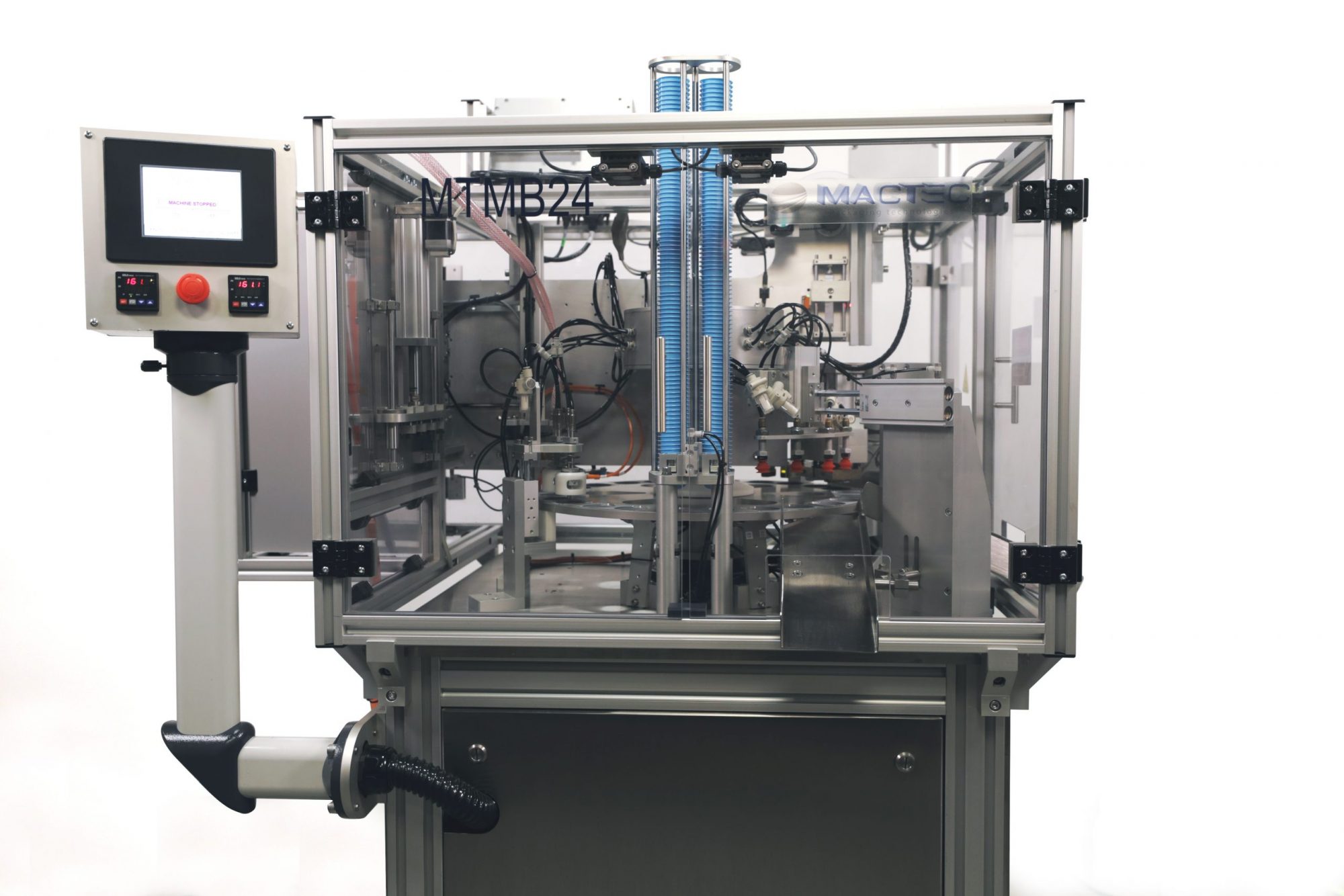

Extremely versatile blister packaging solutions for liquids, gummies, powders and solids. Both thermal-forming or cold-forming capabilities.

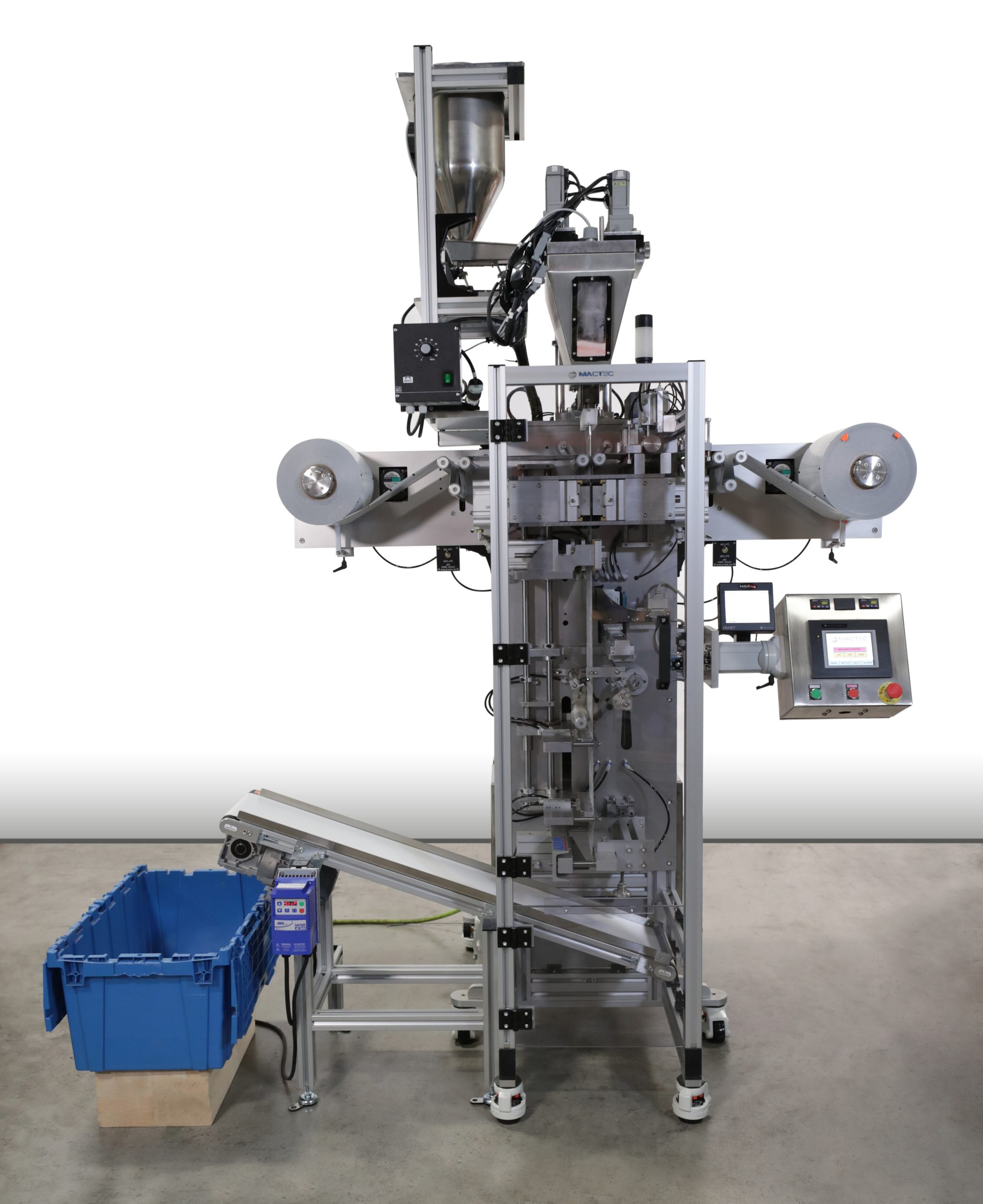

Our vertical-fill pouch packaging machine provides the flexibility you need to get your solid, liquid, or powder unit dose product in a sample pouch or sachet and out the door.

Custom designed for your product whether it's cups (fill and seal), tubes (fill and crimp), or bottles and vials (fill and cap), our monoblocks will exceed expectations.

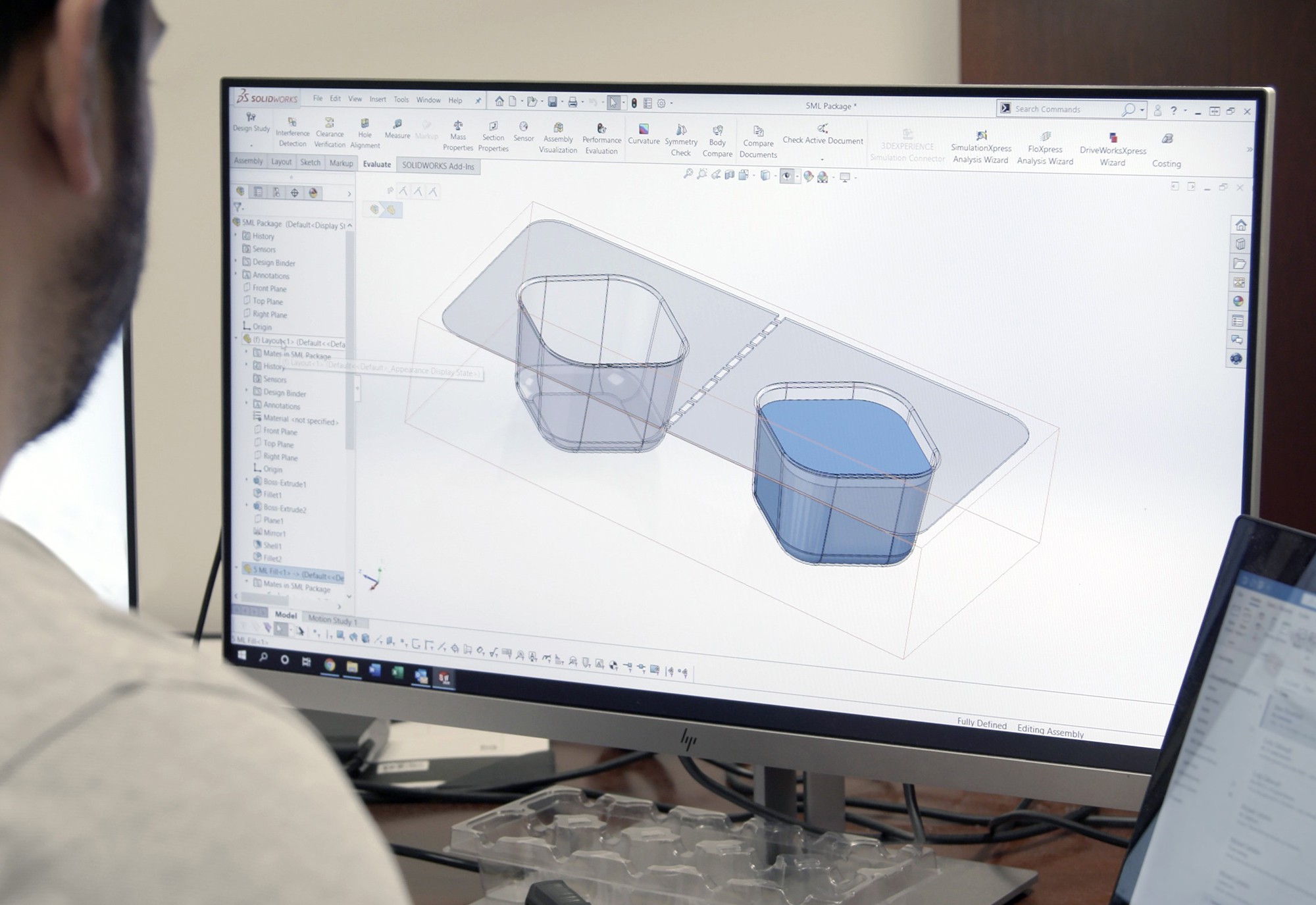

At Mactec, we serve a variety of industries and understand the specific design work that needs to go into each product. Some customers come to us with the exact dimensions of what they need for each component, others utilize our design and engineering team to help finalize their packaging. Wherever you are in the process, we can work with you.

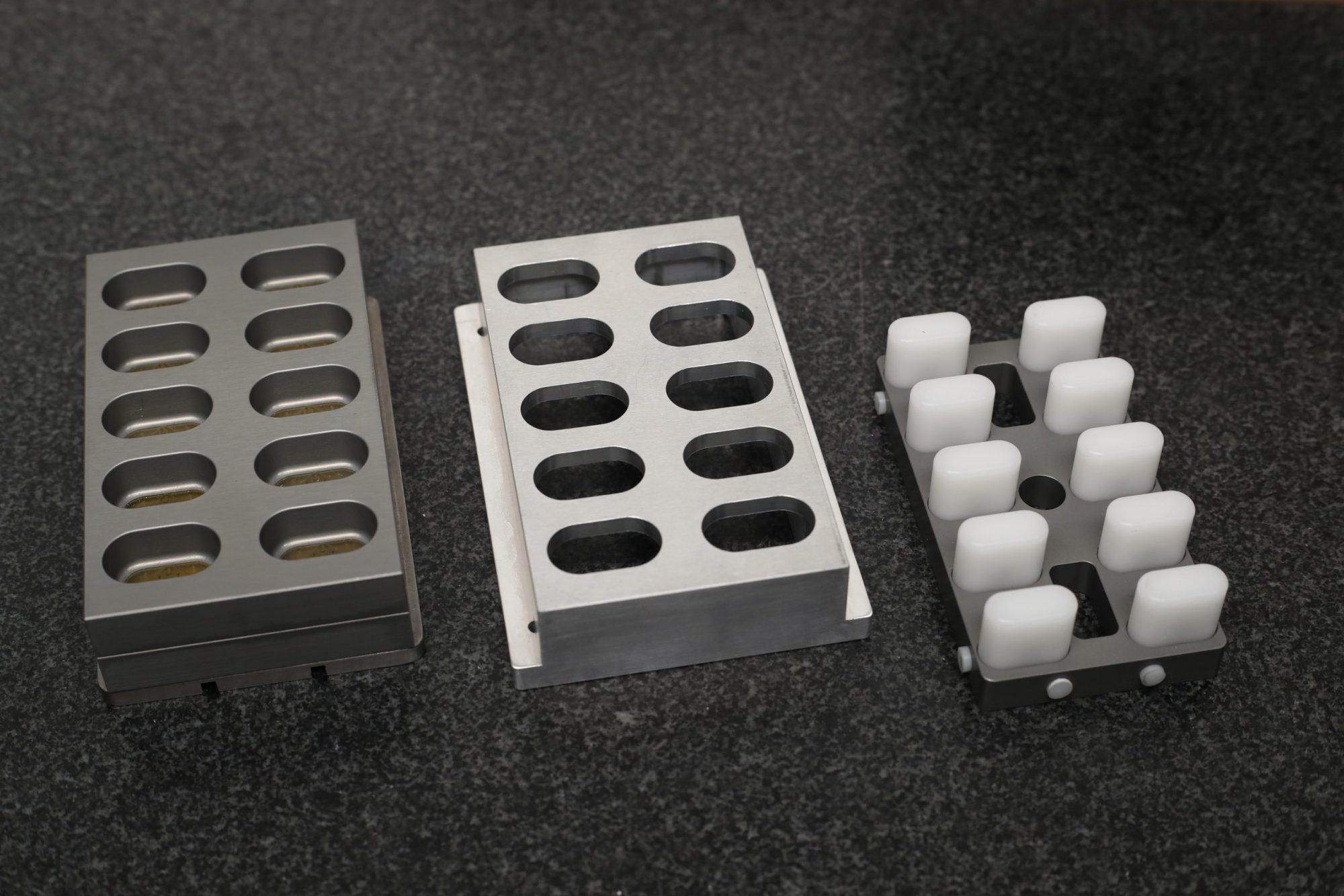

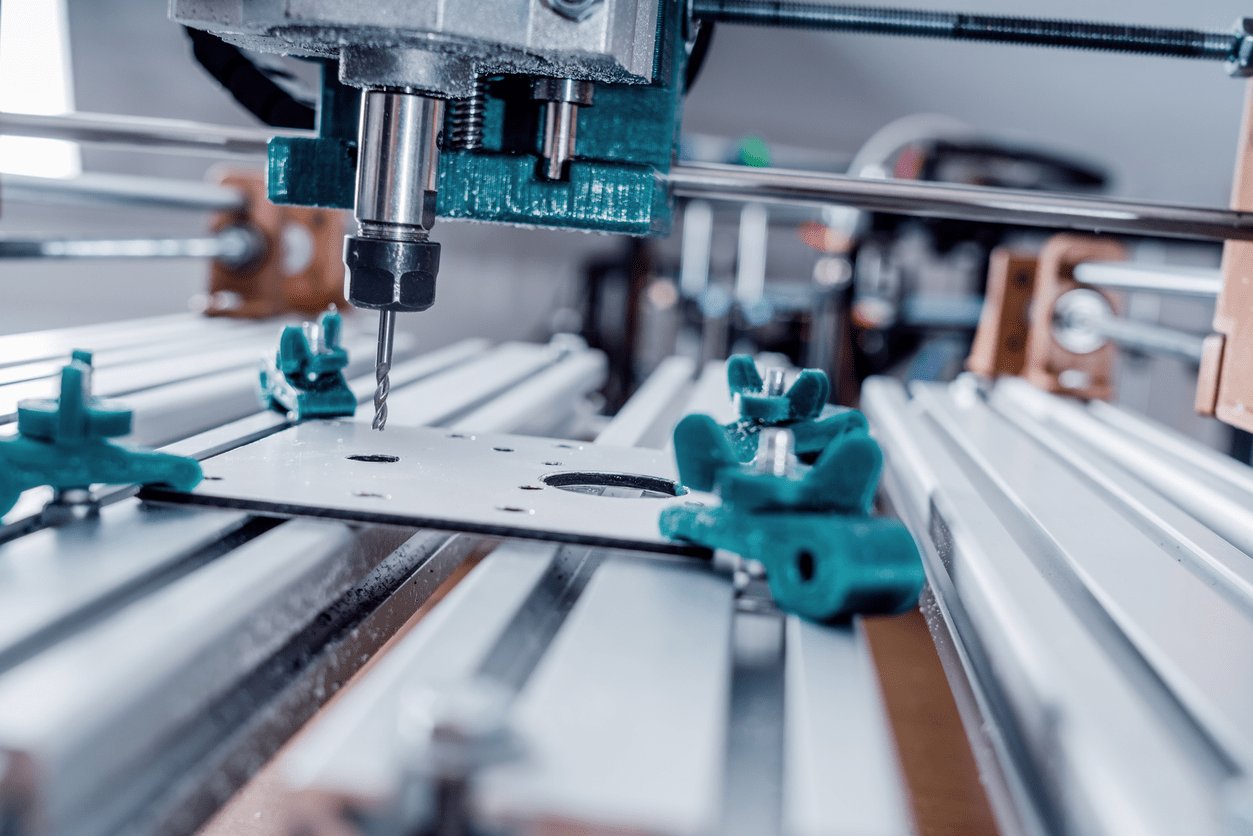

Our custom tooling options allow operators to quickly run a different product in minutes.

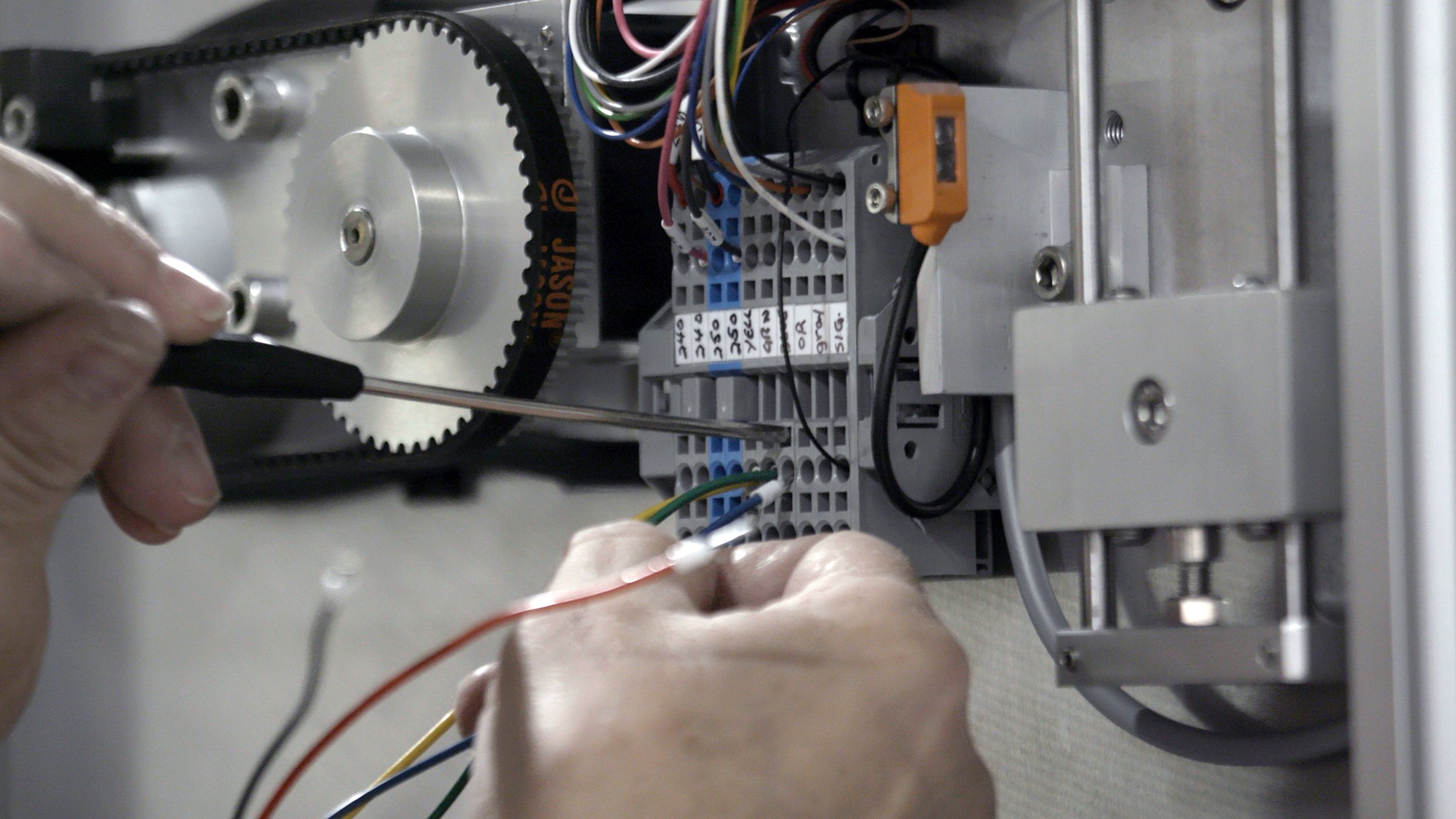

On-site visits to ensure streamlined start up and satisfactory testing.

Retrofit your machine to accommodate changes in your production.

We have decades of experience to guide you towards the best packaging for your product.